>

>

>

>

2024.01.04

Hyundai Motor kick-starts year at Korea’s first EV-only factory

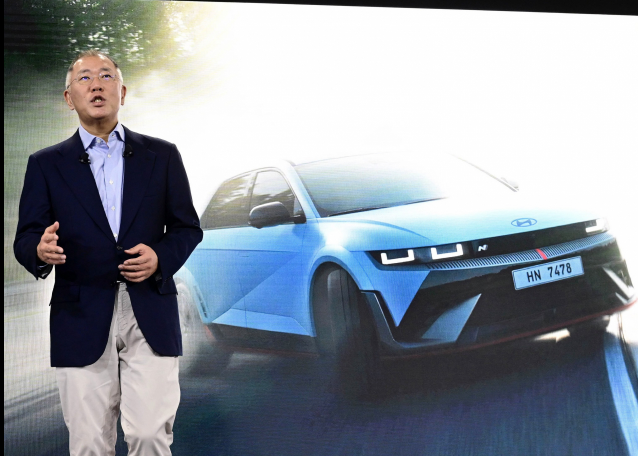

By Moon Joon-hyun, The Korea Herald - Hyundai Motor Group kick-started the year with a New Year's address on Wednesday at Kia AutoLand Gwangmyeong, South Korea’s first dedicated electric vehicle factory, with Executive Chair Chung Euisun and other top executives sharing the company's vision and commitment to electrification and future mobility.

The Hyundai chief

reaffirmed the group's focus on "constant change" and

"sustainable growth" as key strategies to thrive amid global

uncertainties and intense industry competition. He emphasized the importance of

the Gwangmyeong factory in spearheading Hyundai’s electrification journey,

starting in Korea and expanding globally.

“Starting the year

at Gwangmyeong, our first dedicated EV plant, is symbolic. We’re eagerly

anticipating the waves of electrification innovation that will ripple from here

to Ulsan, the US and beyond,” he said.

Plant 2 in Kia

AutoLand Gwangmyeong, a historic site in Korea's automotive industry since 1973

in Gyeonggi Province, is transitioning into a fully dedicated EV facility in

the first half of this year. This transformation coincides with Kia's 80th

anniversary and the 50th anniversary of its first passenger car, the T-600.

This shift

represents a significant step in Hyundai Motor Group's strategy to become one

of the top three global EV manufacturers by 2030. The factory is set to produce

a more affordable lineup of two new EV models -- the compact crossover EV3 and

the midsize sedan EV4 -- with an annual capacity of 150,000 units for both

domestic and international markets.

Sustainable growth

and social responsibility were also at the heart of Hyundai Motor Group's

vision that Chung presented.

“Sustainability

isn't just a buzzword for us; it's about survival. We're doubling down on

carbon neutrality and the circular economy to grow sustainably alongside

humanity,” he said.

This vision includes

advancing a hydrogen ecosystem, promoting clean energy solutions, and

spearheading recycling initiatives, especially for EV batteries. These

initiatives align with the group's broader environmental commitments, targeting

carbon neutrality by 2045.

Hyundai E&C, for

instance, has been expanding its renewable energy trading business, while

Hyundai-Kia is actively reducing carbon emissions in its manufacturing

processes, partly by adopting solar power systems across its facilities.

In addition to

environmental considerations, Chung emphasized not to lose sight of the

fundamental role of product and service quality in winning customer trust.

“Quality is our

cornerstone. It’s always about delivering more than expected,” Chung said.

Kia Motors Corp. CEO

Song Ho-sung detailed the innovations at the Gwangmyeong EV plant, such as

streamlining logistics through automated control systems and reducing carbon

and hazardous emissions.

Worker-friendly

measures are also a priority, he said, with the implementation of low-load and

low-noise equipment to minimize physical strain and noise pollution. For

pre-checking safety risks, Boston Dynamics' Spot robot will navigate through

the plant, identifying potential hazards and ensuring safety protocols are

maintained.

“Armed with such

cutting-edge technologies, we anticipate AutoLand Gwangmyeong to be a key

player in popularizing EVs, with our EV3 and EV4 models leading the charge,”

said Song.

At the address,

other executives like Shin Jae-won, head of the advanced air mobility division,

discussed plans to launch its urban air mobility unit Supernal’s vehicles in

the US market by 2028 and called attention to Supernal's upcoming showcase of

its urban mobility vehicles at CES 2024 next week.

Head of the Global

Strategy Office, Kim Heung-soo, expressed commitment to developing humanoid

robots capable of real-time environmental adaptation for future adoption in

factory sites, showing a video of Boston Dynamics' humanoid robot, Atlas,

handing a work tool to a human.

Source: https://www.koreaherald.com/view.php?ud=20240103000686